EXPANSION JOINTS

EXPANSION JOINTS

Our expansion joints are made entirely of non-asbestos materials. Their composite construction provides durability with increased flex fatigue life over comparable systems, and avoids insulation loss due to shake-down or compaction.

GT Exhaust Expansion Joints

The James Walker Townson range of gas turbine exhaust joints and the adjacent steel parts offer unique solutions to problems such as high temperatures, large movements, pulsations, vibrations and water washing.

Comflex® Multilayered Fabric Wraps

Comflex® wraps provide a rapid economic solution to the problems of failed expansion joints.

Comflex® PTFE Expansion Joints

- Single layer joints with an inner surface of PTFE films that are crossed and laminated to produce the ultimate chemical and indestructible barrier.

- With a zero porosity inner face, that is capable of performing from -73°C to +316°C, this is the ultimate material for harsh chemical condition.

Elastomeric Expansion Joints

- Resistance to moisture and chemical corrosion.

- Resistance to flutter and pulsations.

- Hard wearing products.

- Range of materials to suit different applications.

- Availability in roll form for on-site installation and

joining. - No need for an internal sleeve.

- Extended expected life.

- Ideal products for fan discharge and turbine inlet applications.

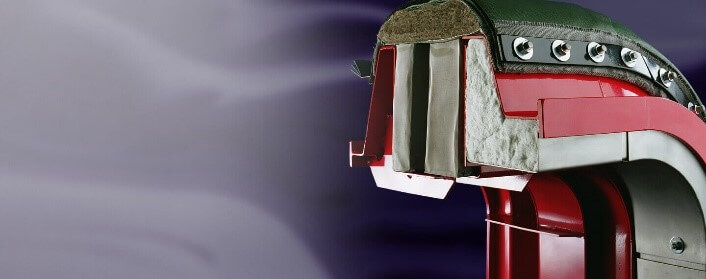

HT/XA Expansion Joints

- These products are used on gas turbine exhausts (power generation and marine duties), boiler roof top seals, rotary air heater internal seals for power stations, and furnace exhausts at steelworks.

- Complex HT/XA Bellows are one of the few expansion joints that can be insulated over at elevated temperatures.